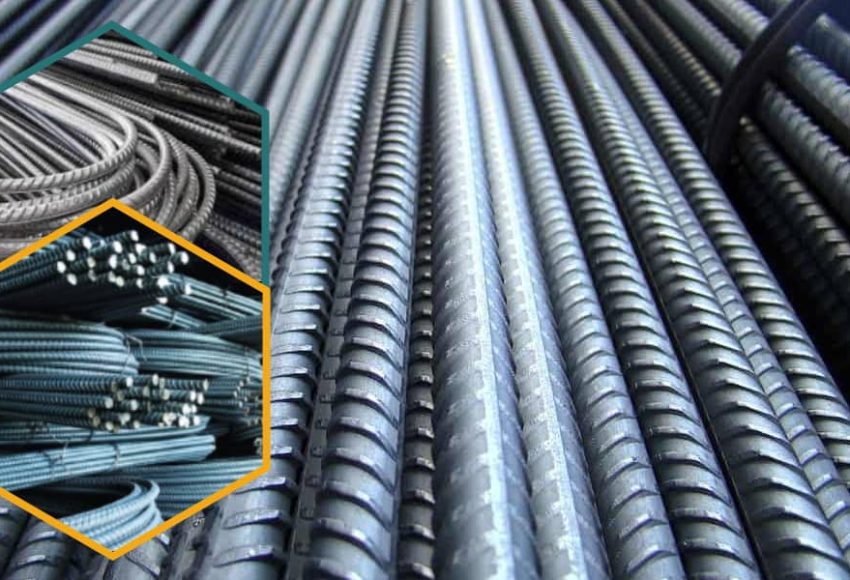

Structured Steel Bar: Common Types of Steel Bars

The strongest type of steel Bar for the building is known as structural steel. It is made to handle enormous weights and withstand bending and twisting. A variety of construction categories, such as stadiums, bridges, and buildings can use it.

Commonly, steel bars are of two types:

Steel bars made of mild steel:

In strengthened cement structural work, mild steel bars are utilized for the maximum strength of RCC (Reinforced cement concrete) slab beams, etc. These steel bars range in diameter from 6 to 50 mm and have a flat surface. Such rods may be swiftly and damage-free cut and bent since they are produced in vast lengths.

Multiple Categories of mild steel bars:

These kinds can be used to categorize reinforcement bars that adhere to IS No. 432 Part-I standards.

- Mild Steel Bars: Two categories of mild steel bars are available.

- Mild steel bars of grade I, often known as Fe 410-S or Grade 60

- Grade II steel bars, often known as Grade 40 or Fe-410-o

- Moderate steel bars: with the Fe-540-w-ht or Grade 75 designations

It is not advisable to utilize Class II mild steel bars in railways, bridges, or other structures that are vulnerable to dynamic loads (other than wind loading). It might incur considerable damage from earthquakes.

Each delivery or lot of mild steel bars put to the site must pass laboratory testing prior to use in the project. Nonetheless, one can utilize mild steel bars for minor projects provided. They validate the test results from the manufacturer’s testing, which are accessible from the provider.

Several producers branded the quality of MS bars with their brand or name and provided test and grade certification. According to the information above, mild steel bars can be stored at the worksite in grades.

Welded steel bars:

Welded steel bars are known as steel rods with hooks, ribs, or other deformations on the link between the two components are known as welded steel bars. Tensile stresses on deformed bars are higher than on normal mild steel bars. It is possible to utilize these bars without end hooks. Along the bar, the deformation should be separated at essentially regular intervals.

It is typical to employ deformed bars that have protruding ribs or are twisted to enhance the bond with the concrete to reduce fractures that may occur in strengthened concrete over mild steel bars due to reducing fractures that may occur in reinforced concrete around mild steel bars as a result of stretching of the bars and some loss of bond under load. These bars are made in portions ranging in diameter from 6 mm to 50 mm.

Moreover, computed bond strengths for deformed bars should be 40 to 80% greater than those for ordinary round bars with the same standard size. Moreover, it has a higher tensile stress than plain circular bars with the same regular shape.

Structural engineers advise using cold twisted deformed (Ribbed or Tor Steel Bars) bars as the best structural steel for construction projects.

Other types of Steel bars:

HSD (High-Strength Deformed Steel Bars):

Choose HSD Steel Bars to assure the durability and caliber of your home’s construction since they are made from cold-twisted deformed bars with lugs, ribs, projections, or other surface deformations. The features, strengths, and creation of HSD bars are discussed in this article.

Bars with a thermomechanical treatment: (TMT bars)

Are you seeking strong bars to build your house with? Choose reinforced cement concrete (RCC) work that uses thermo-mechanically treated bars. They are high-strength-shaped steel bars.

Using Steel Bars in RCC Work:

All final steel bars must be precisely rolled to the required dimensions and weights for reinforced construction. They ought to be solid. Additionally, they are free from laminations, hard jagged, defective edges, and other problems. It needs to be completed in a manly manner.

Reinforced Steel Bars Precautions:

- Steel bars are clean and free of light mil dimensions, dust, and loose rust layers of paints, oils, or other coatings that might obliterate or weaken the bonding power.

- To minimize deformation, degradation, and corrosion, steel bars should be kept in a certain manner.

- To eliminate rust, steel bars shouldn’t be cleaned with an oily material.

- The bar is properly and appropriately bent to achieve the size and shape depicted in the drawings.

- When feasible, the complete length of the bar is utilized.

- Overlaying bars should be maintained separately from one another with concrete so that they don’t contact.

- If specified, the overlap ought to be spaced out.

- The use of spots is required to maintain the position of the cranks in the bar at the finish.

- It is important to avoid disrupting the steel bars while they are laying in cement.

- When placing the cement concrete, provide the necessary shelter under the steel bars.

- No overlap is provided in bars with a diameter of more than 36 mm; welding should be done to the bar if necessary.

The weight of several steel bars:

The vendor gives a price quote in weight when we go to the market to buy mild steel components.

Whenever any kind of steel component is needed for use in building a house. We compute its length in feet or meters but are unaware of the steel’s weight.

Information on weights per meter for several steel component types is provided below:

This will assist in estimating the cost and weight. Avoiding weight theft at the point of purchase will also be helpful.

- 22 kg in the round bar, 0.28 kg in the square bar of 6 mm diameter

- 8 mm 0.39 kg for round bar and 0.50 kg square bar

- 62 kg round bar to 0.78 kg square bar in 10 mm

- Round bar of 0.89 kg to square bar of 1.13 kg in 12 mm

- 58 kg round bar 2.01 kg square bar 16 mm

- 46 Kg and 3.14 kg in 20 mm for round and square bars respectively

- 85 kg round bar and 4.91 kg square bar, in 25 mm

- 83 kg round bar 6.15 kg square bar in 28 mm

- 32 mm has 6.31 kg in the round bar while 8.04 kg in the square bar

- 99 kg round bar, steel bar of 10.17 kg, in 36 mm

- 86 kg round bar, 12.56 kg square bar, in 40 mm

- 90 kg in the square bar while 12.49 kg round bar in 45 mm

- 15 kg round bar, 19.62 kg square bar, in 50 mm

How can one confirm that steel element weight is accurate?

You must be aware of the size and value of mild steel structures before you buy them for your home’s building. Since the shopkeeper lists pricing for steel components based on weight. The anticipated weight and price of structural steel components are described in depth in this article.

Conclusion:

Steel is made up of carbon and iron. Therefore, it is hard, reliable, and strong. Being structural steel, it shouldn’t have cracks or damaged surfaces with uneven borders.

If you want durable steel bars or structural steel that can stiffen your construction. Then you should contact H.S. Group for any kind of building material. Other than steel, we also distribute clinker, aggregate, cement, etc. Moreover, we are available for the export of mines and minerals too. We can offer you copper ore, iron ore, steam coal, marble and granite.